In industries where even a small variation can affect safety, performance, or compliance, the quality of raw materials becomes non-negotiable. This is especially true when working with hydrated lime, a material widely used in chemical processing, pharmaceuticals, water treatment, and other precision-driven environments.

Not all hydrated lime behaves the same way. Differences in purity, particle size, and production control can directly influence results. This is where Shri Jodhpur Lime stands out as a trusted source of high purity hydrated lime designed for applications where accuracy truly matters.

Why hydrated lime quality matters in precision-based industries

Precision industries operate within tight limits. Whether it’s maintaining a stable pH, controlling reaction speed, or ensuring product safety, the margin for error is extremely small.

When hydrated lime quality fluctuates, it can lead to:

- Inconsistent chemical reactions

- Difficulty in process control

- Higher rejection or reprocessing rates

- Compliance and safety concerns

This is why hydrated lime for high precision applications must be produced with greater care than general-grade lime used in construction or basic industrial work.

The role of purity in controlled industrial processes

Purity is one of the most critical factors when selecting hydrated lime for sensitive applications. High purity hydrated lime ensures that the material reacts predictably without interference from unwanted minerals or contaminants.

This is important because impurities can:

- Alter reaction behaviour

- Affect pH stability

- Interfere with formulations in pharmaceuticals

- Reduce efficiency in chemical processing

Understanding why high purity hydrated lime is important for precision applications helps industries minimise operational risk and maintain consistent output quality.

How consistency and particle size affect performance

Beyond purity, consistency plays a major role in how hydrated lime performs. Hydrated lime with consistent particle size disperses evenly, reacts uniformly, and allows accurate dosing.

Controlled particle size helps in:

- Achieving faster and more uniform reactions

- Reducing material wastage

- Improving process repeatability

- Maintaining batch-to-batch consistency

For industries that rely on exact measurements, predictable performance is just as important as chemical composition.

Production control and quality assurance standards

Shri Jodhpur Lime follows controlled manufacturing processes that focus on uniform hydration, proper milling, and regular quality testing. As an ISO certified hydrated lime manufacturer, each batch is monitored to ensure it meets industrial requirements.

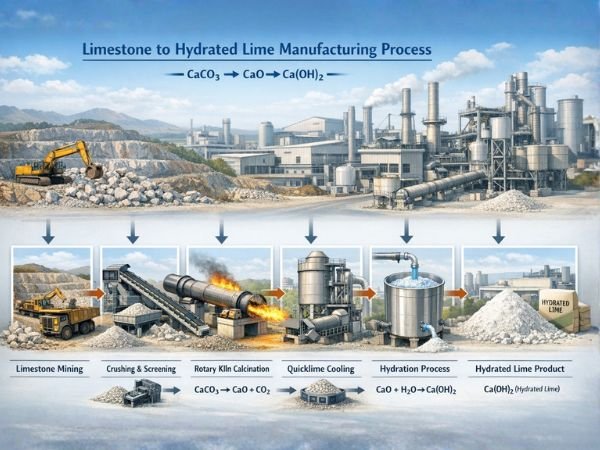

The material maintains the standard hydrated lime chemical formula Ca(OH)₂, ensuring chemical stability and reliability across applications. These quality checks allow industries to use hydrated lime confidently in regulated environments.

What can go wrong with low-grade hydrated lime

Using general or poorly processed hydrated lime in precision applications can lead to serious challenges. Low-grade material may contain impurities, uneven particle sizes, or inconsistent moisture levels.

This can result in:

- Unstable reactions

- Equipment scaling or blockage

- Reduced efficiency in water treatment

- Formulation issues in pharmaceuticals

This clearly shows how hydrated lime quality affects industrial performance, especially when accuracy and safety are priorities.

Key industries that depend on precision-grade hydrated lime

| Industry | Why precision-grade hydrated lime is required |

| Chemical industry | Controlled reactions and pH regulation |

| Water treatment | Reliable neutralisation and purification |

| Pharmaceutical applications | Safe, stable formulations |

| Specialty industrial processes | Consistent and repeatable outcomes |

Because of these needs, many consider Shri Jodhpur Lime among the best hydrated lime for pharmaceutical and chemical industries.

Why Shri Jodhpur Lime is trusted for high-precision applications

As a reliable hydrated lime supplier for industrial use, Shri Jodhpur Lime combines traditional expertise with modern quality systems. Their focus on purity, consistency, and testing ensures industries receive material that performs the same way every time.

Rather than supplying generic lime, they cater to applications where precision, safety, and compliance are essential making them a dependable partner for high-accuracy industrial needs.

Frequently Asked Questions

Q1. Why is high purity hydrated lime essential for precision applications?

Answer: High purity hydrated lime ensures stable reactions and predictable performance. In precision industries, even small impurities can affect product quality, safety, or compliance. Using high-purity material reduces these risks and improves process reliability.

Q2. Is hydrated lime suitable for pharmaceutical applications?

Answer: Yes, hydrated lime for pharmaceutical applications is used when produced under strict quality control. Purity, consistency, and testing are essential to ensure it does not interfere with sensitive formulations or safety standards.

Q3. How does particle size impact hydrated lime performance?

Answer: Uniform particle size allows even dispersion and accurate dosing. This improves reaction control and reduces wastage, especially in chemical processing and water treatment applications.

Q4. Can hydrated lime be used effectively in water treatment?

Answer: Absolutely. Hydrated lime for water treatment helps control pH, remove impurities, and improve overall water quality when sourced from a reliable, quality-focused manufacturer.

Q5. What makes Shri Jodhpur Lime suitable for industrial use?

Answer: Their controlled production process, ISO certification, and focus on consistency make them a trusted hydrated lime supplier for industrial use, especially for high-precision environments.

Q6. How stable is hydrated lime during storage?

Answer: When stored properly in dry conditions, hydrated lime with the correct Ca(OH)₂ composition remains stable and effective for long-term industrial use.