What Is Lime and Why It Matters in ETPs

Lime, especially hydrated lime (calcium hydroxide) and quicklime (calcium oxide), is one of the most trusted materials in industrial water treatment systems. While it’s widely known in construction and agriculture, its role in Effluent Treatment Plants (ETPs) is equally important but often overlooked.

Using quality lime in effluent treatment plants helps control pH, reduce heavy metals, remove phosphorus, and improve the overall efficiency of the system. But it’s not just about using lime it’s about using the right kind of lime, from the right manufacturer, like Shri Jodhpur Lime, who understand the demands of industrial-scale treatment.

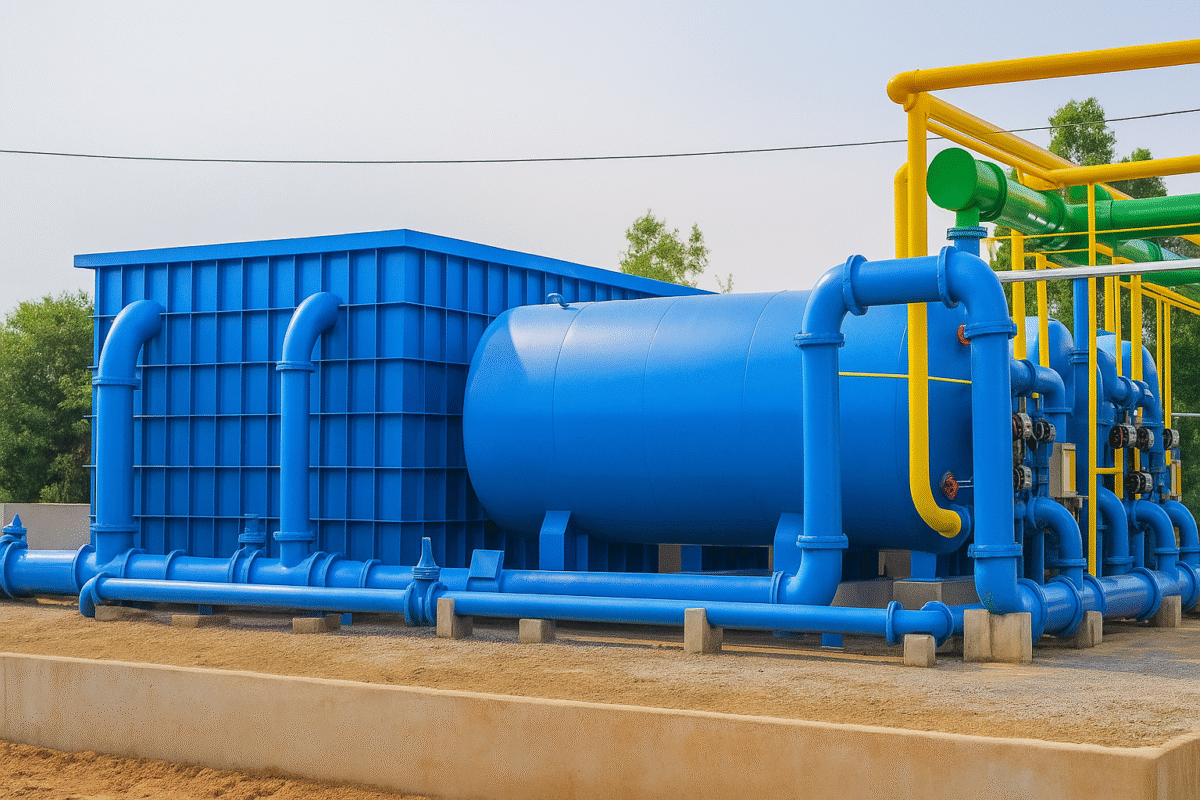

Understanding Effluent Treatment Plants (ETPs)

Effluent Treatment Plants are designed to treat wastewater coming from industrial processes like textile dyeing, pharmaceuticals, chemicals, food processing, and more.

This wastewater usually contains:

- High acidity or alkalinity

- Suspended solids

- Heavy metals (like lead, mercury)

- Oils, greases, and organic contaminants

An ETP works in multiple stages: preliminary, primary, secondary, and tertiary treatment. Lime is commonly introduced during the primary treatment stage when solids, acids, and metal contaminants are removed.

How Lime Works in the Effluent Treatment Process

Here’s how lime in Effluent Treatment Plants actually works:

- pH Neutralisation: Lime raises the pH of acidic wastewater to neutral levels (typically around 6.5 to 8.5), which is essential for further biological treatment and discharge compliance.

- Coagulation and Flocculation: Lime helps suspended particles clump together and settle. This process removes turbidity and prepares the effluent for clearer output.

- Heavy Metal Removal: By raising the pH, lime causes many dissolved heavy metals to precipitate as insoluble hydroxides.

- Phosphate Removal: Lime reacts with phosphorus in the water, helping form insoluble compounds like calcium phosphate that can be easily filtered out.

- Pathogen Control: In some cases, the high pH achieved through lime dosing can kill bacteria and pathogens.

These chemical reactions are well-known, but the effectiveness depends heavily on the quality of the lime used.

7 Key Benefits of Using Quality Lime in ETPs

1. Reliable pH Control

One of the biggest challenges in industrial wastewater is maintaining the correct pH. Using high-grade lime ensures faster reaction time, better control, and minimal overdosing.

2. Efficient Metal Precipitation

Impurities like iron, copper, and zinc are harmful to the environment and need to be removed before discharge. Quality lime ensures consistent precipitation, avoiding fluctuations in metal levels.

3. Cost-Effective Operation

Although it might seem like a more expensive material upfront, top-quality lime reduces the overall chemical consumption, speeds up reactions, and minimizes the need for secondary treatments—saving money in the long run.

4. Less Sludge Generation

Poor-grade lime or improper dosing often leads to excess sludge. By contrast, premium-grade lime from an experienced ETP lime manufacturer like Shri Jodhpur Lime results in cleaner reactions and less solid waste.

5. Compliance with Environmental Standards

Using quality lime helps meet local and international discharge norms. It keeps BOD (biochemical oxygen demand) and COD (chemical oxygen demand) levels in check ensuring smooth inspections and avoiding penalties.

6. Multi-Purpose Functionality

Lime doesn’t just serve one function. Its ability to adjust pH, reduce phosphate, and kill pathogens makes it a multi-tasking material, especially useful in sectors like textiles, chemicals, and leather.

7. Longer Equipment Life

Using sub-standard materials can corrode pipes and storage tanks. Quality lime with low impurity content is less abrasive, meaning your infrastructure lasts longer and stays in better shape.

Why “Quality” Lime Makes All the Difference

Not all lime is created equal. There are major differences in:

- Purity levels

- Particle size

- Moisture content

- Reactivity speed

Choosing lime with consistent composition ensures:

- Precise dosing

- Faster settling of solids

- Lower consumption rates

Shri Jodhpur Lime is known across industries for supplying high-purity lime that’s perfect for effluent treatment. Their products meet strict industrial standards, and are tested for chemical performance, ensuring peace of mind for plant operators.

Common Applications of Lime in Different Industries

Lime is widely used in industries such as:

- Textile Manufacturing: For removing dyes and controlling pH

- Pharmaceuticals: For treating chemical-laden wastewater

- Tanneries: For heavy metal and chrome removal

- Paper & Pulp: For reducing COD and bleaching agents

- Food Processing Units: For neutralising acidic effluents

In each of these industries, the role of lime is slightly different, but its effectiveness depends entirely on quality and consistency.

Choosing the Right Lime Supplier for Your ETP

When choosing a lime supplier for your Effluent Treatment Plant, consider these criteria:

- Consistency in quality: Look for certifications and lab reports

- Experience in industrial supply: Providers like Shri Jodhpur Lime understand the challenges of ETPs

- Custom solutions: Some industries may need quicklime, others hydrated lime

- Reliable logistics: Lime is best used fresh and in the right form—delay in supply affects ETP performance

A dependable ETP lime manufacturer will not only supply material but also guide your team in proper usage and dosage, ensuring optimal outcomes.

FAQs

Q1. Is lime the best chemical for wastewater treatment?

Answer: Lime is one of the most effective and versatile chemicals for ETPs, especially for pH control, metal removal, and phosphate treatment. It’s widely used due to its cost-effectiveness and proven results.

Q2. What type of lime should I use in my ETP—hydrated or quicklime?

Answer: It depends on your setup. Hydrated lime (Ca(OH)₂) is easier to handle and safer, while quicklime (CaO) offers higher reactivity. Consult your supplier or plant engineer for recommendations.

Q3. Can I use agricultural lime in my ETP?

Answer: No. Agricultural lime isn’t processed or purified for industrial use. It may contain impurities that interfere with chemical reactions or harm equipment.

Q4. How much lime do I need for effective treatment?

Answer: Dosing varies based on the pH and composition of your wastewater. A lab test is essential for determining the right amount. Overdosing can lead to unnecessary sludge and increased costs.

Q5. How does lime compare with caustic soda or alum?

Answer: Lime is often preferred for its lower cost and environmental friendliness. While caustic soda acts faster, it’s more expensive and corrosive. Alum is good for flocculation but doesn’t offer pH control like lime.

Q6. Does lime treatment affect the environment?

Answer: When used correctly, lime improves environmental outcomes by neutralising harmful compounds. However, excessive lime or improper sludge handling can pose risks—hence the importance of proper dosing and disposal.

Q7. Why choose Shri Jodhpur Lime for ETP lime supply?

Answer: They are a trusted name in the lime industry, known for consistent quality, timely delivery, and technical support. Their lime is used in ETPs across textile, leather, chemical, and food sectors.

Conclusion

Using quality lime in Effluent Treatment Plants isn’t just good practice it’s smart engineering. Whether you’re tackling high-acidity waste, heavy metals, or phosphorus overload, the right lime makes all the difference.

By partnering with a reliable ETP lime manufacturer like Shri Jodhpur Lime, industries can cut costs, reduce downtime, and stay compliant with environmental laws.

If you’re planning to upgrade your ETP system or troubleshoot performance issues, start with the basics: the quality of your lime. It’s not just a chemical; it’s a cornerstone of clean, compliant, and cost-effective wastewater management.